I’m not going to beat around the bush: Volvo Buses will deliver the world’s first 100% electric bi-articulated buses in 2025. It’s a game-changer for BRT: 92 feet long, up to 550 passengers, 400 kW of power, and up to 720 kWh of batteries. It’s big, quiet, and yes, it’s seriously impressive.

What makes the BZRT the first true electric bi-articulated bus?

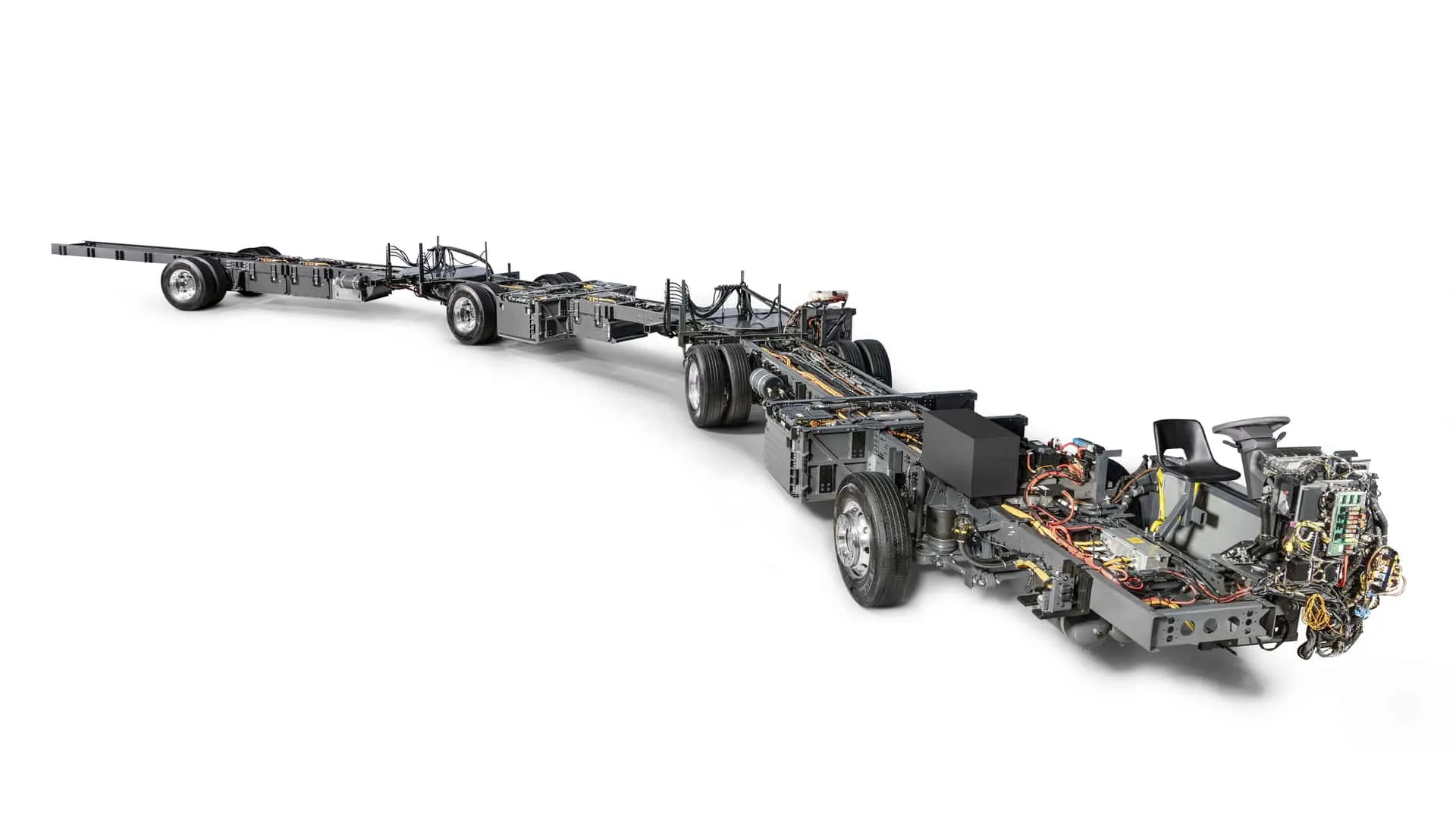

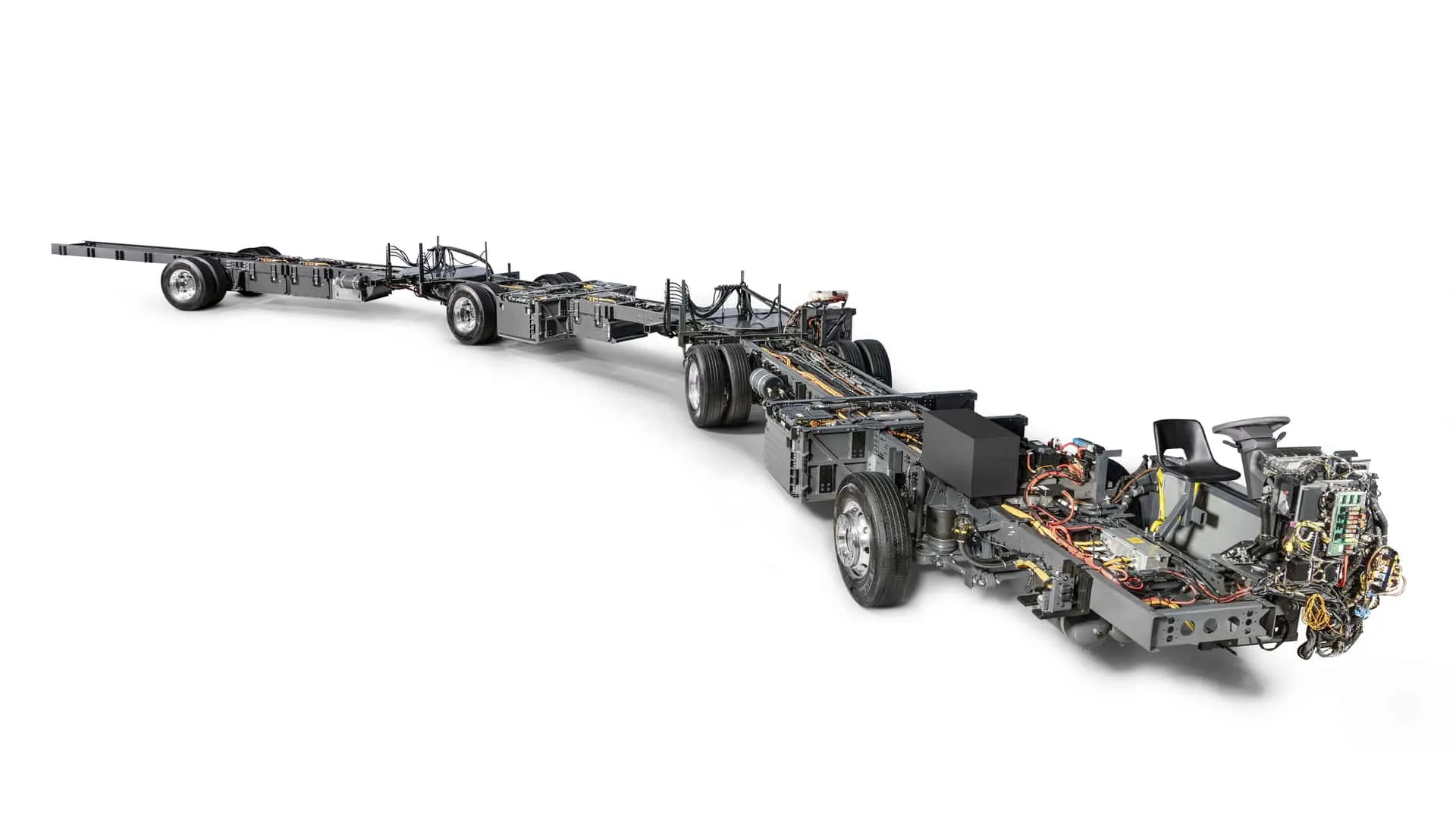

The BZRT is built for high throughput: a 92-foot (28 m) bi-articulated with a declared capacity of up to 550 people (or 180 in the articulated section). The chassis was designed for high-demand BRT systems, with a centralized powertrain and batteries in the floor, freeing up space and balancing weight. The result? A more open floor, better circulation, and comfort without that infernal noise of a combustion engine.

In the powertrain, there are two electric motors of 200 kW each (total of 400 kW / 540 horsepower) and up to eight battery modules totaling 720 kWh. This provides a robust urban range with zero CO₂ emissions from the exhaust and very low noise — the kind of silence felt on the first city block. By the way, the premium electric DNA seen in SUVs from the brand also enhances this sense of quality, like in the Volvo XC90 prepared by Heico Sportiv.

How does this powertrain deliver 400 kW and up to 720 kWh in real life?

The package is modular: the platform can accept up to 8 batteries (720 kWh) and two drive axles with 200 kW motors each. This allows configuring range and performance based on route cycle and topography. Integrating batteries into the floor lowers the center of gravity and improves stability — essential when carrying the equivalent of a regional plane on wheels.

In actual operation, range depends on factors like temperature, load, driving style, and topography. Still, global e-bus data shows that the technology’s maturity is here, with consistent gains in efficiency and cost per km, as noted in the IEA’s Global EV Outlook 2024.

Capacity, comfort, and noise: can it hold 250 people without pain?

Yes, and the layout helps. With the motor and batteries “under the floor,” the cabin remains cleaner, and flow improves during peak hours. Electric acceleration is smooth, without jerks, and noise drops dramatically — your eardrums thank you, and so do residents along the route. It’s a noticeable quality leap that we already see in passenger electric vehicles with good insulation and refined powertrains, similar to the premium electric SUVs like the EQB.

Capacity is more than just numbers: it involves boarding times, door ergonomics, traction control algorithms, and torque distribution on wet pavement. The BZRT integrates all these features with active safety systems that are not just bells and whistles: they prevent accidents, reduce wear and tear, and keep operations smooth even when demand is, to be frank, crazy.

What safety and automation systems make a difference in BRT?

The BZRT is equipped with cameras to expand the driver’s view, pedestrian and cyclist detection, license plate reading, and Volvo Dynamic Steering (VDS), which helps maintain precision even with full occupancy. It also includes GPS-enabled Safety Zones that automatically reduce speed in critical areas. This “invisible hand” saves time and lives.

In this era of software-driven and electrically capable platforms, the shift to systems increasingly defined by software can already be seen in long-range passenger EVs, like the Audi A6/S6 e-tron family. This digital ecosystem arrives in buses to manage torque, regenerative braking, speed, and safety in dedicated lanes.

Infrastructure and operation: can you charge such a giant?

Yes, but not casually. High-capacity operations require planning: overnight depot charging with high power levels and, when appropriate, opportunity pantographs at the end of the route. With a maximum of 720 kWh, the key is to balance charging power, operational windows, and battery temperature to avoid damage and keep TCO under control. Architecturally, it’s the same principle as large electric vehicles with high DC charging power and smart thermal management, similar to luxury electric SUVs like the Wagoneer S.

To size the fleet properly, simulation tools for cycle planning are essential. And it’s crucial to follow best practices within the electric public transport sector, as outlined by global organizations like UITP in their e-bus guide. In short: robust infrastructure, efficient thermal management, real-time telemetry, and trained operators. Without this, it’s just patchwork — and patching high-volume systems leads to disaster.

Technical highlights in 20 seconds

- 92 ft (28 m) and high-demand BRT

- Up to 550 passengers (bi)

- Two 200 kW motors (400 kW)

- Up to 720 kWh of batteries

- Batteries in the floor

- Zero local emissions

- VDS and Safety Zones

- 360° cameras and sensors

BZRT vs. common electric articulated buses

- Capacity: 550 vs ~330-370

- Length: 92 ft (28 m) vs ~59 ft (18 m)

- Battery: up to 720 vs ~370-500

- Power: 400 kW vs ~250-330

- Flow: bi-articulated vs articulated

- Stability: VDS and weight management

- Safety: GPS zones

Quick FAQ

- What’s the total power? 400 kW (two 200 kW motors) with smooth delivery and high traction.

- Battery capacity? Up to 720 kWh, with scalable modules depending on the route.

- How many people?” Up to 550 in the bi-articulated; about 180 in the articulated section.

- How does it reduce accidents? VDS, 360° cameras, pedestrian/cyclist detection, and GPS Safety Zones.

- How is it charged? Mainly at depot with DC fast charging; may use opportunity pantographs at end of route, depending on operations.

If you’re looking for evidence of electric momentum in transportation, also see the paradigm shift with icons transitioning from combustion engines to radical electric models, like the V8 engine Corvette’s leap to EV. The entire industry is shifting gears — including the heavyweights.

My view: the BZRT hits the mark where BRTs struggle — capacity, noise, efficiency, and safety. The engineering is solid, the numbers are credible, and the battery modularity offers tactical flexibility for different routes. The challenge? Robust infrastructure and operational discipline. If the operation is lazy, range will evaporate, and costs will rise. If well managed, it becomes a global benchmark. That’s it.

Liked it or disagree? Leave your comment: what matters most for you in an electric BRT — range, comfort, safety, or cost?

Author: Fabio Isidoro

Founder and editor-in-chief of Canal Carro, he dedicates himself to exploring the automotive universe with depth and passion. A car and technology enthusiast, he produces technical content and in-depth analyses of national and international vehicles, combining quality information with a critical eye for the public.