An internal combustion engine that dispenses with oil? Ford developed this technology with ceramics and a gas cushion. See why it didn’t work out.

- How did Ford’s oil-free engine work? It used a gas cushion instead of an oil film, with ceramic parts to withstand high temperatures and reduce friction.

- What materials were used in this project? High-rigidity, low-thermal-conductivity ceramics, such as silicon nitride and silicon carbide.

- Why wasn’t the concept mass-produced? Challenges with microscopic tolerances, machining costs, and functional limitations prevented its commercial viability.

- What is the current impact of this concept? The study inspired advances in efficiency and friction reduction in modern engines, even without large-scale adoption.

- Were there direct competitors to this concept? Other experimental ceramic engines sought similar solutions, but no street-legal automotive model went beyond the prototype stage.

Imagine an internal combustion engine that never sees a drop of oil, intentionally operates hot, and eliminates friction losses from piston rings. Yes, Ford almost got there in the 1980s with a revolutionary project that swapped the traditional oil bath for a thin gas cushion, promising extreme efficiency and almost zero maintenance. The theory was ambitious: less fluid, less mess, more performance. But, after all, why did this innovation never make it to the streets?

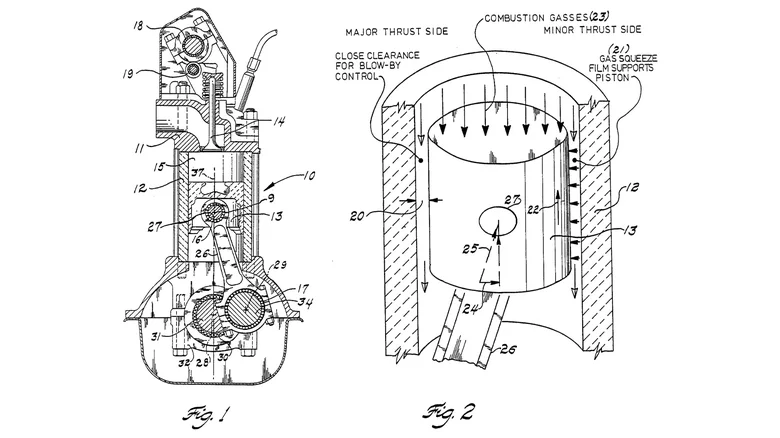

The solution seemed ingenious: using ceramic pistons and cylinders, the Ford project created a micro-gap between moving parts, using the piston’s own movement to draw air through micro-channels – forming the so-called “gas squeeze film,” a gas cushion that separated the components without the need for oil. This, combined with the use of materials like silicon nitride and zirconia, allowed it to operate at high temperatures, leading to less mechanical loss and cleaner combustion. If realized, it could have redefined how we know internal combustion engines.

From a technical standpoint, the “oilless” engine project eliminated piston rings, operated with microscopic clearances (around 0.025 mm), and required ultra-smooth surfaces. The promised result was less than 2% blow-by above 1,500 rpm, something unprecedented even by today’s standards. However, maintaining this micro-gap under heat, vibration, and dust was a true engineering nightmare.

Unlike modern hybrids or electric powertrains, which already occupy a prominent space among efficient alternatives, such as the advancement of Rimac’s solid-state batteries, the gas film engine never moved beyond paper due to the high costs of ceramics, the difficulty of precise machining, and low tolerance to impurities and internal impacts – in addition to the need for oil for cooling and cleaning the remaining parts of the powertrain.

Besides Ford, other engine manufacturers experimented with similar ceramic and oilless engine concepts in the final decades of the 20th century, but all ran into the same barrier of large-scale viability. Curious to know about other automotive concepts that defied the rules? Access the article on drawer engines that tried to launch electric cars in the 1920s.

Specifically, the Ford “oil-free” engine would feature:

- High-rigidity ceramic parts

- Operating temperature up to 1,600 °C (2,912 °F)

- Piston-to-cylinder clearances of 0.001 inches

- Elimination of conventional piston rings

- Maximum reduction of internal friction

Comparison: Ford Oilless Engine vs. Traditional Combustion Engines

- No lubricating oil vs. Full lubrication

- Resistant ceramic vs. Cast iron/aluminum

- High-temperature operation vs. Constant cooling required

- Extreme manufacturing challenges vs. Consolidated mass production

- Low blow-by vs. Medium/high emission of unburned gases

Today, the pursuit of the ultra-low friction engine continues in the industry, whether with composite materials, ultra-thin oils, or pure electrification, as seen in the rise of SUVs like the hybrid Renault Clio. The legacy of the “oilless engine” is present in innovations aimed at thermal and environmental efficiency.

And you, do you believe we will still see a 100% oil-free engine in the future of automobiles, or has electrification already left this dream behind? Leave your comment and share your opinion on how far engineers’ boldness goes!

Author: Fabio Isidoro

Founder and editor-in-chief of Canal Carro, he dedicates himself to exploring the automotive universe with depth and passion. A car and technology enthusiast, he produces technical content and in-depth analyses of national and international vehicles, combining quality information with a critical eye for the public.